Blackhorse Lane Ateliers

The only brand in the world that is able to put the ‘Made in London’ tag on their jeans? Blackhorse Lane Ateliers. Named after the street that their little factory is located on in Walthamstow, London is owned and operated by a longtime denim maker, Han. Pulling together a team of skilled tailors, pattern cutters and machinists with little to no experience in denim, Han created a brand making arguably the best quality denim in the world (which they will be able to prove through their extensive knowledge). Having a local atelier and sourcing their denim from mills around Europe allows Blackhorse Lane Ateliers to be completely transparent to demonstrate the distinctive excellence of their jeans. Join us on a tour of life on Blackhorse Lane and find out more about denim!

The story of Blackhorse Ateliers begins with Han, who bought the factory over 20 years ago. After having worked for high street brands for a while, he was asked to move production first to Turkey, then to China and later on to Vietnam. Eventually Han decided it was time for him to get out of the fashion industry and moved back to London to open a restaurant in Stoke Newington called Homa, focusing on organic produce. Wanting to get back to doing something creative, he started Blackhorse Lane Ateliers, a community driven venture that has a focus on making locally and unparalleled quality. He saw an opportunity after noticing that the jeans on the market at that time weren’t great, and that he had the resources, the skills and the know how to refine the art of jean making.

“We really want this to be like open source fashion or kind of like collaborative fashion” says David, who takes care of the PR, marketing and sales of the brand. “It’s all about this kind of community and collaboration that also goes a step further with the businesses we work with. It’s kind of like cross pollination”. Blackhorse Lane Ateliers houses a kitchen spearheaded by Pedro who introduces pop up dining events at the factory, a textile weaving brand called SR Wovens and many other creatives in a variety of fields. Blackhorse Lane Ateliers sees strength in the cooperative nature of their business; “Sophie Hawkins you could consider her to be a competitor just because she’s designing womens workwear, but in actuality we’re collaborating with her on some of the garments”. What the denim makers are creating is something “where the sum is larger than the individual parts” David offers up.

when we make our jeans we don't want them to be something that only the fashion elite can own

Blackhorse Lane Ateliers was built upon three core values; quality craftsmanship, sustainable materials and staying accessible and affordable. Having a factory in London with experienced tailors and using raw organic cotton and European mills for their denim aided this mission. Offering a lifetime repair service makes sure Blackhorse Lane Atelier jeans will never end up in the landfill. What they were about to offer was a spin on the heritage denim making traditions with the addition of the know how of the tailors. Han saw this was the perfect time to bring a new kind of denim to the market: “It’s a garment for everyone and it’s something that seems like it’s ripe for a revolution”. What currently existed was simply not as good as it possibly could be. David, who is a so called ‘denim head’ says that he has never seen a product like Blackhorse Lane jeans before: what most excited me about Blackhorse lane is seeing the quality. So I’ve got maybe 15 or so pairs of jeans at home I’ve collected over the years and they’re all special for some reason but none of them have the production quality as high as our team’s. So they’re literally the best jeans in my collection quality wise”.

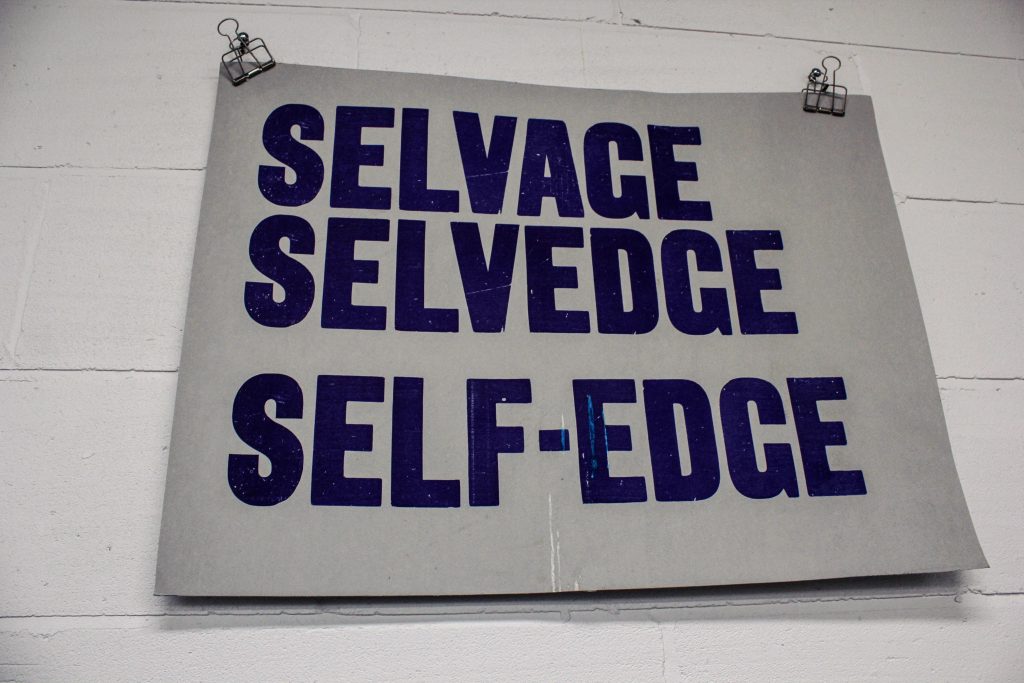

The main thing that sets Blackhorse Lane apart however, is their construction. They looked to the Anglo world and Japan to compare and contrast the best of their denim production, and created something with bits from both as well as their own take. “We’ll kind of grab the best from the heritage construction but also use our background in tailoring to kind of make something better” explains David. Having tailors instead of seasoned denim makers allowed to look at the production process from a fresh perspective. “We brought the one piece fly into production which was actually designed and patented back in 1877 but no one does it just because it takes more time it takes more effort. That means the jeans cost more. But for us we felt that the aesthetic and the kind of functional aspects of that design warranted taking the time to do it”.

Naming their jeans after neighbourhood postal codes further engraves the local community into their jean making and products. Each product is designed to fit a certain type of person or lifestyle, and the brand engages with their customers intimately to find out what their unique requirements are. They are dabbling with growing their own indigo, and make everything as locally as possible: “all of our jeans we have our pocket bags silkscreened in Tottenham by Fifth Column” says David. “I live in Walthamstow so it’s the idea that there is someone making jeans in my neighbourhood is amazing”. Blackhorse Lane Ateliers organise community events where people can learn indigo dyeing and jeans making at the factory with some of the most experiences people in the industry. The factory employees are involved in this sense of community as well: “for all the machinist we want them to see us not just as a factory to work for but as like an actual family or like an investment. So all of the machinists have the opportunity to own equity in the business”.

What Blackhorse Lane Ateliers has already done within their field is game changing, but they are not going to stop there. They want to keep inspiring the next generation to pursue denim as well: we’re also trying to inspire more people to get into the trade. “The idea there is inspire new people become jeans makers because over time we’re finding it harder and harder to find people who actually know how to make jeans or are interested in it” says David. “And to me that’s really exciting, this idea of kind of pushing the envelope and making better”